von links nach rechts: Lukas, Stephan und Son

Aluminium Frames

Together for your aluminium frame

I am Son and emboss the individual aluminum profiles with a steel angle to a durable, stable frame. The machine is of course a special design of ours. In addition to a perfect saw cut, it takes the interplay of modern technology and a sure instinct to create a perfect mitre. Finally, each corner is reworked by me personally with small rubber mallet blows until the transition is really perfect. I had to retire my first rubber mallet after over 35 years of service and many millions of blows. This hammer had already touched almost every frame. It now hangs framed in its place of honour on our show wall in the entrance area.

Son

I have worked here since 1986 . My curiosity about how to make a magnetic frame brought me to HALBE. From the first moment I was convinced by the good working atmosphere. I have remained closely connected with the HALBE family throughout the years and generations, and working with the third generation makes me proud. The best moment in all this time was when the boss drove me home. For me, once at HALBE means always at HALBE. I have worked in almost every department, and the responsibility to produce good and beautiful products is especially important to me. One of my favourite frames is a Classic Alu 18 in black, because it is so difficult to emboss and yet I always manage to do it very well.

We are Lukas, Batuhan and Stephan. We are responsible for your ordered aluminium frames. In order to be able to fulfil every one of your wishes, we have many kilometres of profiles in the various shapes and colours ready and waiting in our high-bay warehouse. This means that we can always cut the four correct lengths for each frame from one profile. Of course, the profile cuts are checked for quality beforehand, because a perfect mitre can only be achieved with a clean saw cut. Over the years, we have perfected the rotation and cutting speed so that we can saw a degree-free cut at a perfect 45° angle. We check the tolerances of the profiles and machine every day so that we can deliver a perfectly fitting spare part even after years. Son cannot conjure up a perfect mitre without a clean cut. We contribute to sustainability by recycling all scraps and chips.

Luke

I have only been here since August 2015. My entry point was a student help position, then a year later I started my apprenticeship and was taken on in 2018. During my apprenticeship I worked almost everywhere and am a real all-rounder. One of my favourites among the frames is the Classic Alu 8 in white. Order and cleanliness have become very important to me in all departments, because that's how we can reliably deliver flawless frames.

Stephan

I have been working at HALBEsince November 2003. Because my old employer went bankrupt overnight and I knew someone at HALBE, I got a new job very quickly. My stations were so far the sawing of the aluminum profiles, the basic elements and the dispatch. An old LED frame has accompanied me for many years and one of the special moments was the day I became team leader.

Batuhan

Like many, I've been working here since 2021. I started in upsetting, but have also worked on waterjet cutting and in the wood department. Today I saw the aluminum profiles to size. In my day-to-day work, I attach great importance to accuracy and adhering to tolerances. One of my favorite frames is an Alu 8 CLASSIC in brushed stainless steel.

Batuhan

Like many, I've been working here since 2021. I started in upsetting, but have also worked on waterjet cutting and in the wood department. Today I saw the aluminum profiles to size. In my day-to-day work, I attach great importance to accuracy and adhering to tolerances. One of my favorite frames is an Alu 8 CLASSIC in brushed stainless steel.

How our customers frame

Nils Dunkel at the Kunstakademie...

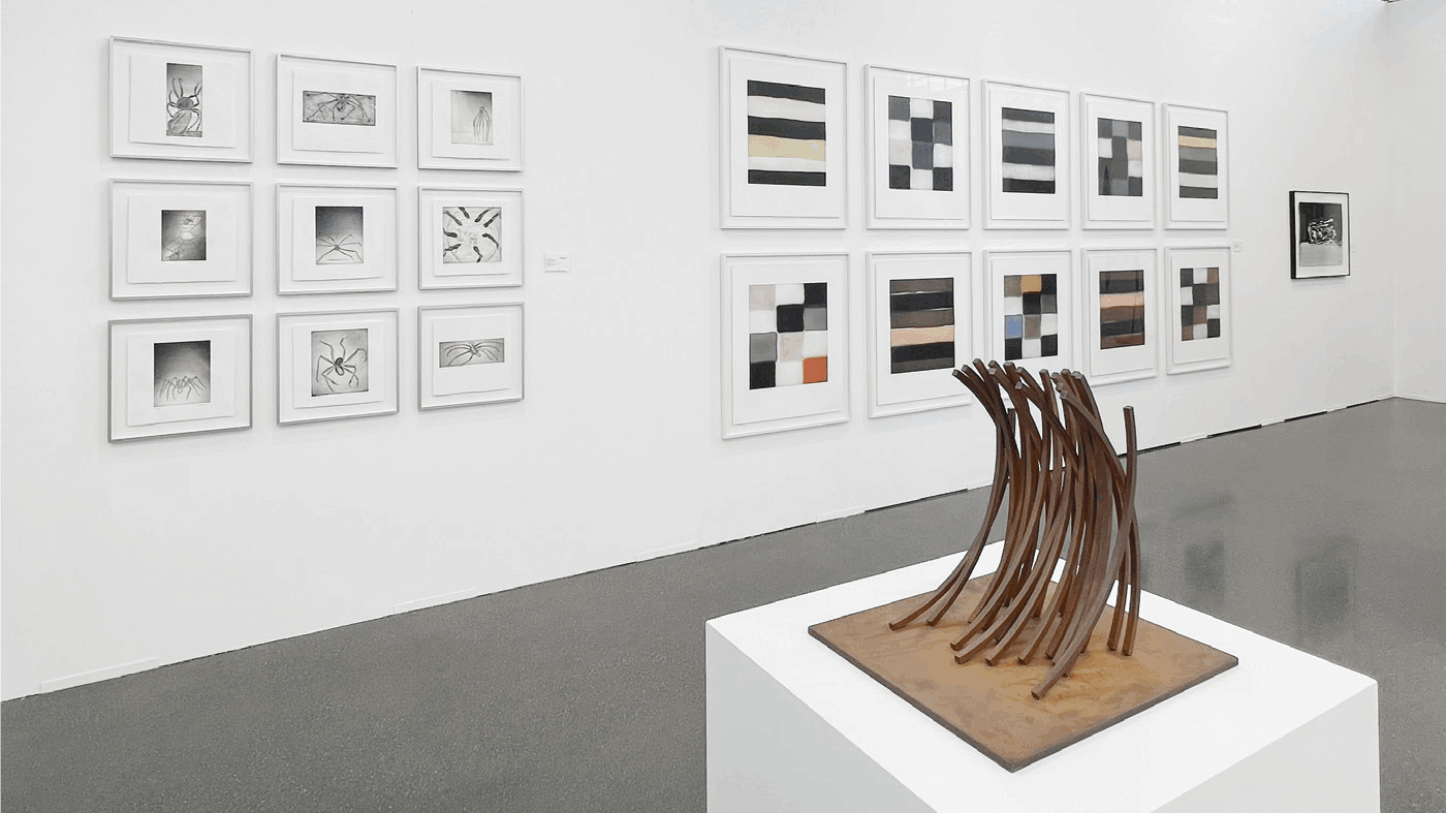

Galerie Boisserée at Art Düsseldorf 2023

Nikola Dimitrov at the Fetzer Gallery

Inspired by Edward Steichen – Erwin...

So rahmen unsere Kunden

Nils Dunkel at the Kunstakademie...

Galerie Boisserée at Art Düsseldorf 2023