Back Panel

A good base for your frame

In order to have space for the suspension later, recesses are drilled into the back panels after cutting. Only after each plate has been cleaned and checked, it gets our logo and the date of manufacture printed on it. Each panel is nested to optimize waste and save resources. We have specially developed the material for this and it is produced exclusively for us. It is harmless for photo paper and has successfully passed the PAT test.

Sergej

I've been working at HALBE since 2021. I was here for a trial day and was allowed to stay. During my time here, I have mainly worked in the basic elements normal and special as well as the wood and glass department. I attach great importance to cleanliness, high quality of the individual materials and quantity. The joy of working is very important to me, as well as the moments when humor is not neglected despite all the work involved.

We are Silvia and Sergej. After an order has been released for production, we are the first stop in the company, because we provide the stable base for your frame. Cutting the back panels for Classic and Distance magnetic frame from hard foam boards is our speciality. They are light, at the same time very stable and absolutely flat - the perfect foundation.

Silvia

I have been part of the big HALBE family since 1999. Before I became a permanent employee, I first completed an eight-week internship. Over the years I have worked in the production of the sheet metal angles, at the glass washing plant, the gluing in of the magnetic tapes and now at the water jet cutting of the back panel. It is especially important that the material is of good quality. But nothing would work without good teamwork and customer satisfaction. My favourite frame is a black Alu Classic 12 in 600x800mm.

How our customers frame

Nils Dunkel at the Kunstakademie...

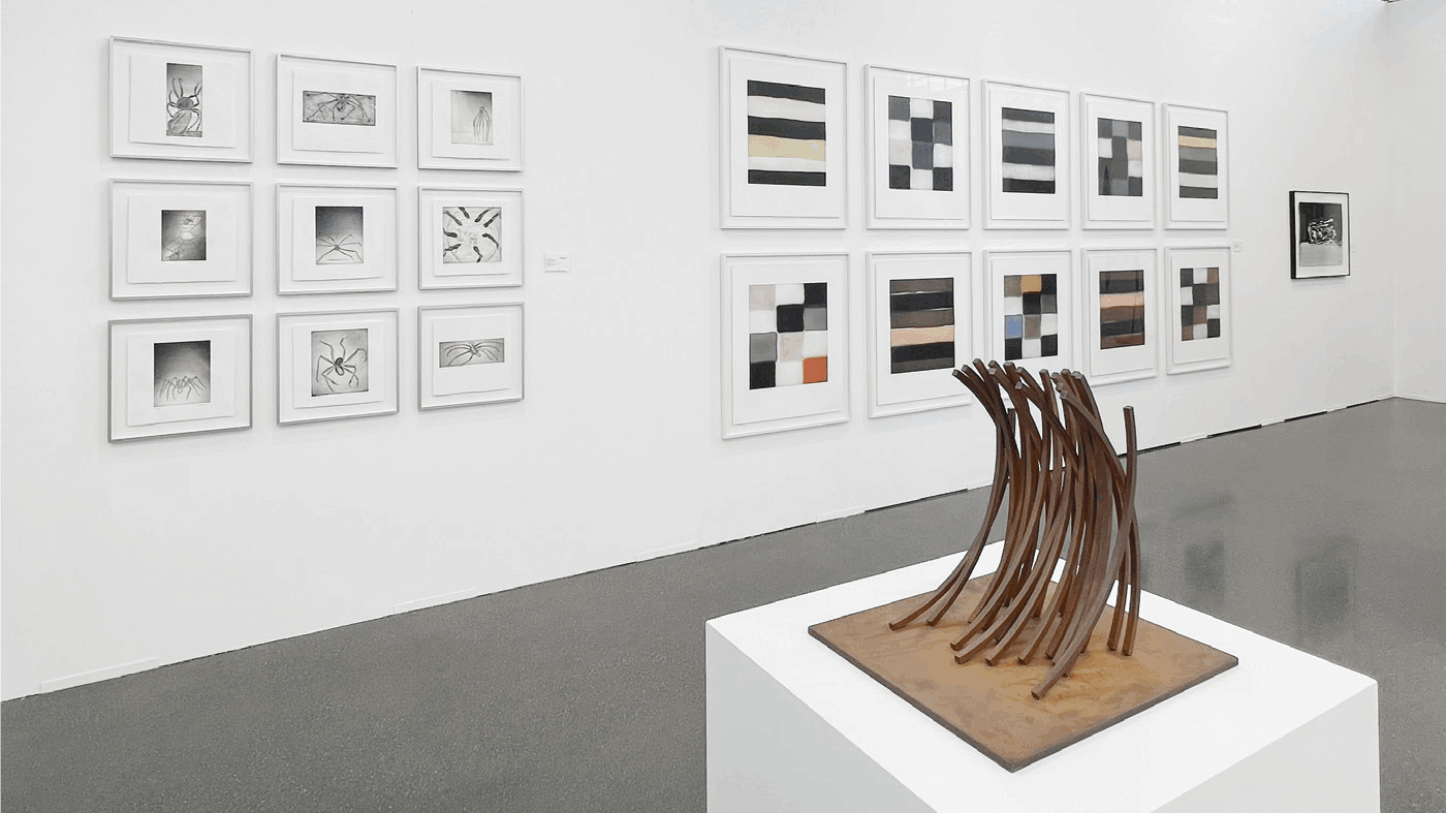

Galerie Boisserée at Art Düsseldorf 2023

Nikola Dimitrov at the Fetzer Gallery

Inspired by Edward Steichen – Erwin...

How our customers frame

Nils Dunkel at the Kunstakademie...

Galerie Boisserée at Art Düsseldorf 2023