from left to right: Birgit, Jutta, Astrid, Eva

Magnetic Strips

The second part to the magnetic force

Before the magnetic strips are glued in place, we check and clean each individual profile and strip very carefully. If a mistake is not noticed during sawing, we will not miss it then. Our claim is to produce only perfect frames for you.

If everything is in order, the magnetic tape is glued in - a special development for us and our big trade secret. Next, we prepare Son's frames for upsetting. To do this, we insert the steel angles in a further step and put the four parts together to form a frame.

We regularly take turns with Sabine and Susanne in the final assembly, so that our large team can draw on a total of almost 170 years of experience.

Birgit

I have been with the company since 1989. Back then I took a course on how to write a proper job application. Apparently the application was so good that Mr. HALBE contacted me a little later and invited me for an interview. My main area today is final assembly, although I have also been in the glass department, basic elements and accessories. I care a lot about making sure the merchandise leaves the company in a timely and orderly manner. Some of the fun and special moments are when you can have fun with your co-workers despite a lot of work. My favourite frame is a 400x500mm Distance in wood 10, in which I have framed each of my children's first baby bodysuits.

We are Birgit, Renate, Astrid and Eva. We are responsible for the second part of the heart of every magnetic frame - the insertion of the magnetic strips. Like the basic element, they are the core of all HALBE frames - whether made of wood or aluminium. To ensure that they can hold their magnetic force permanently, the metal particles are cast in plastic. As a reference, we can show magnetic frames from our HALBE frame collection that are 40 years old and have not lost one bit of their magnetic force since then.

Eva

I have been with the company since January 2003, through the recommendation of a friend who had worked there for 14 years. I only had to do one day's trial work and was then taken on permanently. Since then I have got to know the basic elements department, then the glass and I am also involved in the final assembly. That's how I discovered a Classic 400x500mm in black aluminium and the photo frame for myself. Accuracy, speedy work and punctual delivery to the customer are very important to me. I also value loyalty, reliability, team spirit and communication skills, which are strengthened during the annual company outings and celebrations.

Renate

I've been with the company since January 2021. Before I joined the final assembly department, I was in the basic elements department. In my work, I pay particular attention to the cleanliness, punctuality and quality of a frame. I simply like all the frames because they are so simple and timeless.

Astrid

I have been working here since April 1987. I started with an internship, from 1987 to 2005 I worked in the basic elements department, then for three years on maternity leave and since my return in 2008 in the final assembly. My favourite frame is 400x500 mm. Special moments in all these years? Definitely the fact that I was able to experience two changes of boss and, of course, that I met my husband here.

How our customers frame

Nils Dunkel at the Kunstakademie...

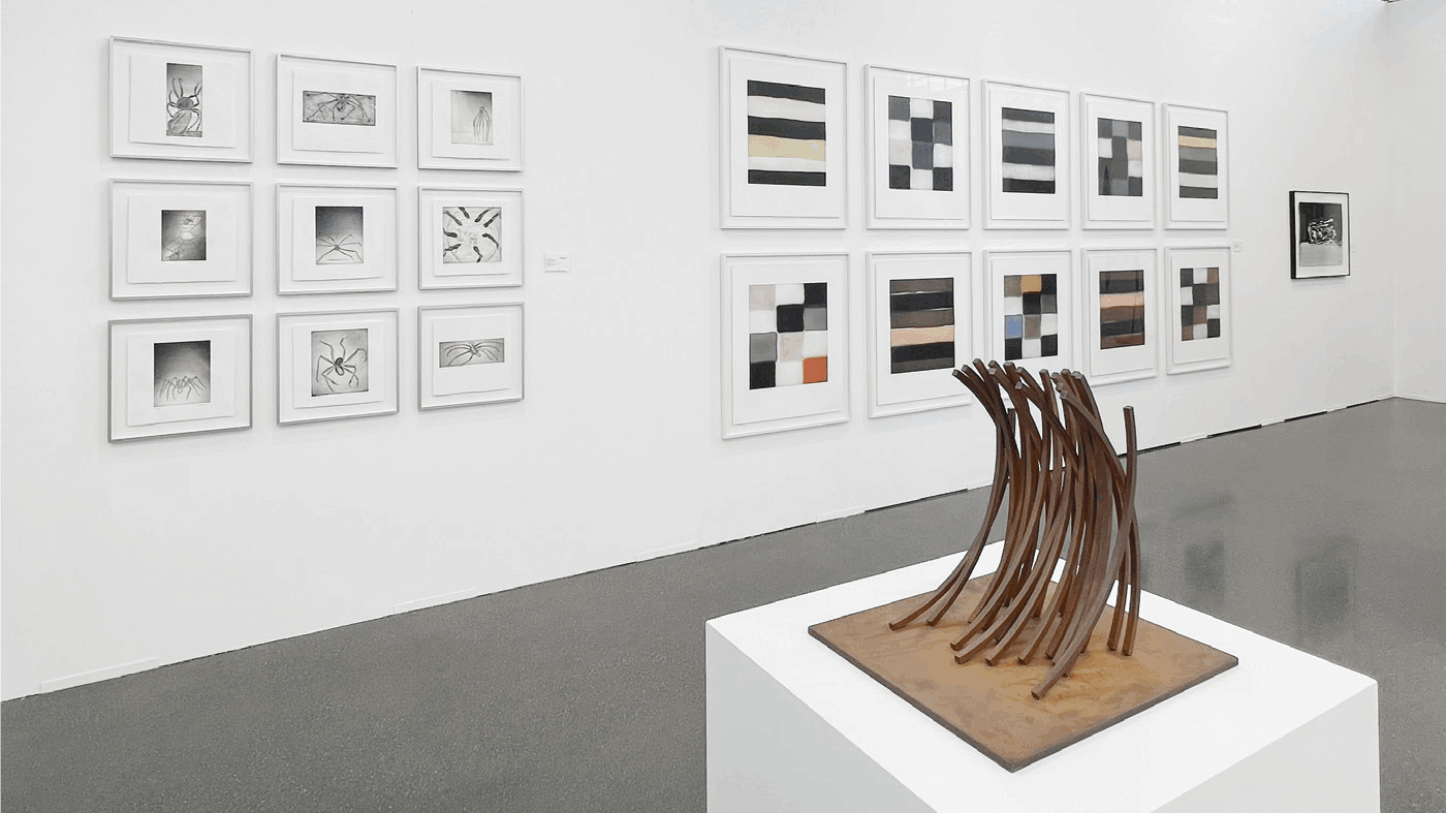

Galerie Boisserée at Art Düsseldorf 2023

Nikola Dimitrov at the Fetzer Gallery

Inspired by Edward Steichen – Erwin...

How our customers frame

Nils Dunkel at the Kunstakademie...

Galerie Boisserée at Art Düsseldorf 2023