von links nach rechts: Savas, Uli und Franz

Basic Element (Professional)

For special requirements

For large projects, such as the new frame for the Munch Museum in Oslo, we develop special frames according to customer requirements. We also manufacture the B1 magnetic frame with a flame-retardant back panel. On our CNC punching machine we can punch out any shape from sheet metal for this purpose. With our CNC-controlled press brakes we then bring the strips into shape. Absolute precision and dimensional control are essential here. Our first punching machine still ran with punched strips. Today, this is hardly imaginable, as everything is now electronically and digitally linked and much more efficient.

Savas

I have been with the company since 2005, starting with an internship, followed by a job as a temp and later I started an apprenticeship. In this way I have worked in every department, and quality and order became very important to me. My favourite frame by far is a photo frame in Alu 4, it simply sets the motifs in scene perfectly.

We are Savas, Dominik and Franz. We manufacture the more complex back panels for our B1, Conservo and Protect magnetic frame or if a special construction is desired. We are the men for the special cases.

Franz

I have been working here since 1994. In the various stations such as the basic elements, the sawing of the aluminium and wooden profiles and the dispatch, I was able to gain a lot of experience and learn what makes our product what it is. Organisation, calm working, competence between supervisor and employee are very important to me. My favourite frames are a display light frame and an art frame. The latter was one of the first passepartout frames. The best moment of my time was when I dropped 200 Art frames and they spread over the entire loading area on the way to coating. I then spent fair amount of time with collecting them all again. Something like that only happens once.

Dominik

Before HALBE, I trained as a cutting machine operator. I have worked in all departments except final assembly. At work, I attach great importance to order and speed. I pay particular attention to maintaining an overview and am always thinking about how work processes can be improved. I like the narrow frames best, which is why I really like the Alu 6 frame with glass 5. The company outings are particularly memorable because you can simply sit together and get to know each other better.

How our customers frame

Nils Dunkel at the Kunstakademie...

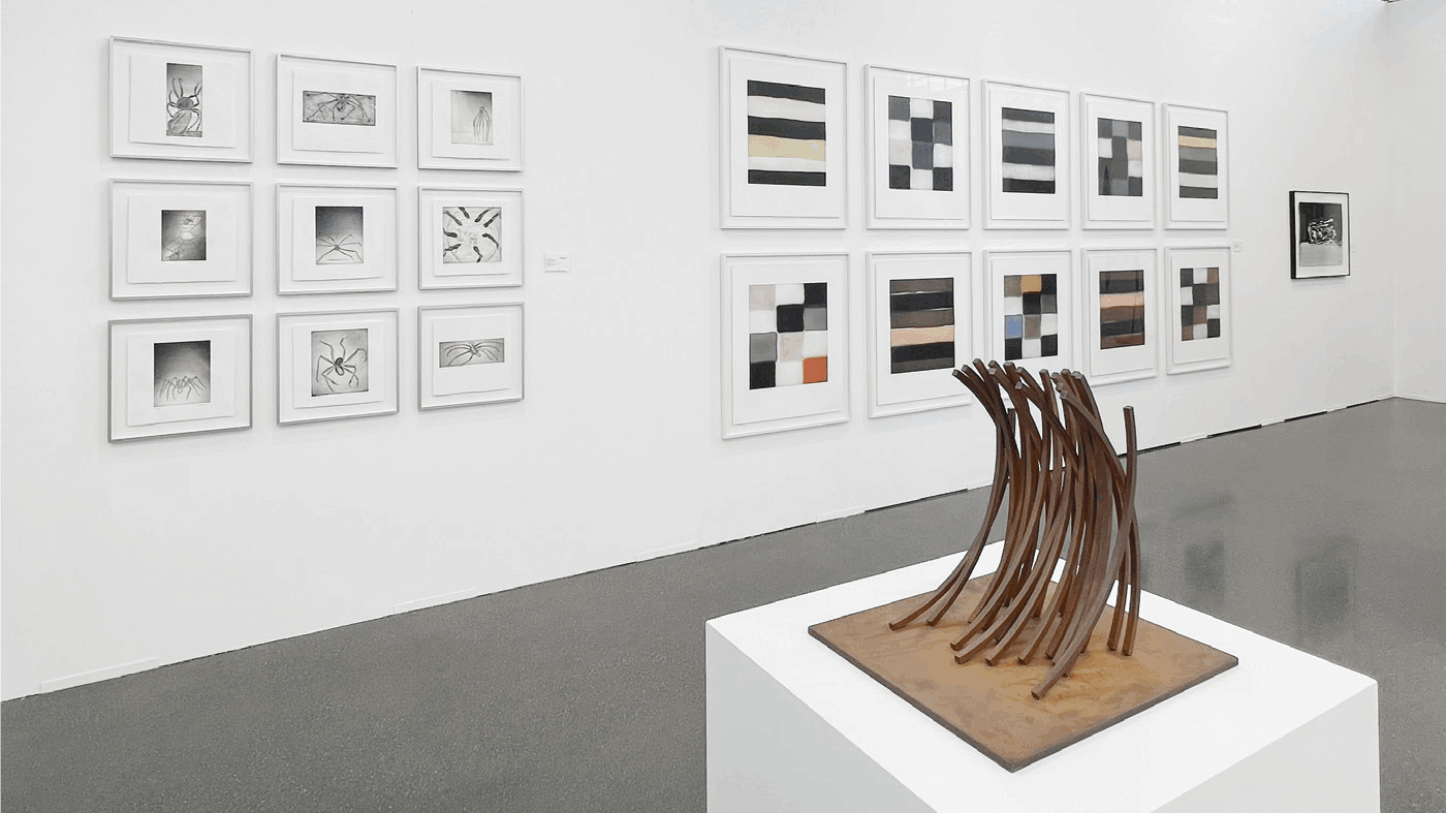

Galerie Boisserée at Art Düsseldorf 2023

Nikola Dimitrov at the Fetzer Gallery

Inspired by Edward Steichen – Erwin...

How our customers frame

Nils Dunkel at the Kunstakademie...

Galerie Boisserée at Art Düsseldorf 2023