A SCIENCE IN ITSELF

The Myth of Glass - Glass for Museums

Why Glass?

Glass plays an important role in framing: it seperates the image from its surroundings and the viewer, so to speak. The tasks of a picture glass are diverse and range from protection against dust and contact to UV protection for the picture. At the same time, it ideally ensures an unclouded view of the picture and should preferably remain invisible when looked at.

Especially in museums, high-quality glass offers indispensable protection for framed paper works. It protects against physical and chemical damage caused by handling and touching, vandalism and theft, UV radiation, dust, dirt, pollutants, smoke or water. At the same time, it should be as invisible as possible.

But not all glasses are the same. The market offers an almost unmanageable number of different types of glass with the most diverse designations. We want to clear the jungle a bit and give you a better overview.

Every glass type described a specific sort of glass combined with a surface. However, in the market of picture frame glass there are no fixed labels and therefore you have to pay very close attention to the offered glass and its specifics.

Three basic materials (normal glass, white glass and acrylic glass), each with three different surfaces (glossy, matt, anti-reflective) are commonly used as picture glass.

Glass as a separation between picture and viewer has a great influence on the effect of a picture. In this article we give an overview of the various types of glass in use and devote special attention to museum glass and its production and use.

The techniques of glass making are very old and date back to ancient times. At first, naturally occurring glass was processed. Already around 1450 B.C. glass was melted from quartz rock and plant ash. Nowadays, glass and its refinement are real high-tech products. Also for the glazing of pictures, high-quality, interference-optical anti-reflective glass - also known as glass for museums - is gaining more and more importance. We provide you with a unique insight into the world of picture glass in this article.

Inhalte

1. Overview of the Different Glass Types

1.1. Why Glass?

1.2. Glass Types

1.3. Surfaces

2.1. Reflection

2.2. UV Protection

2.3. Surfaces

3.1. Weight and Safety

3.2. Lighting

3.3. Cleaning

3.4. Application

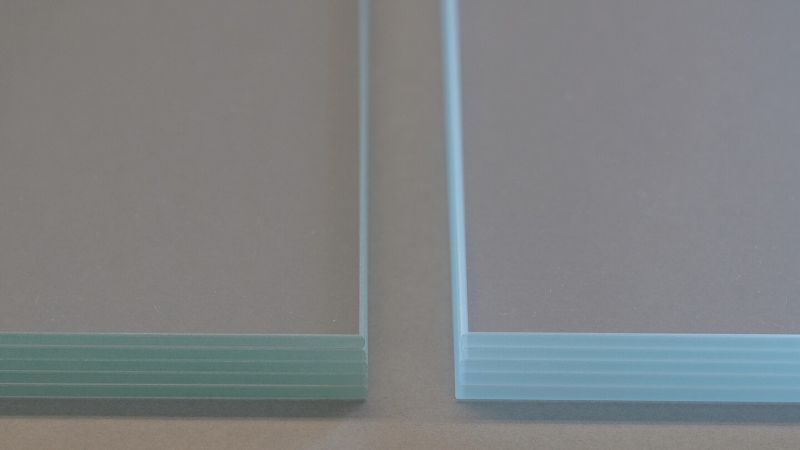

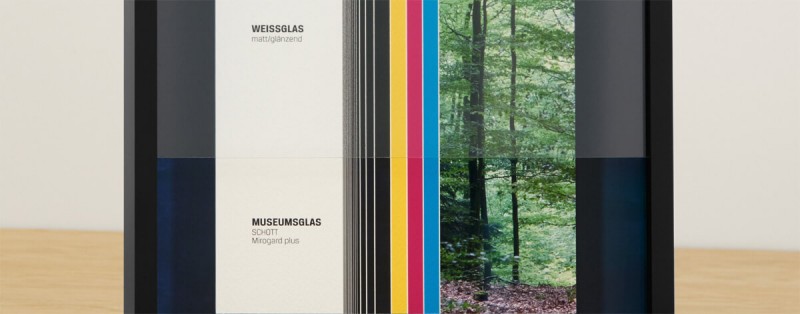

Nomal glass (left) vs. white glass (right)

Glass Types:

"Normal glass", also called "float glass", "mirror glass" or "window glass", stands for a flat glass produced by the float process. Due to its iron content, this inexpensive glass has a slight green tint, which leads to slight color distortion of the framed works.

"White glass", also known as "water white glass" or "clear glass" is of higher quality. In principle, this is also a "float glass", as it is also produced in the float process, but the material composition is different. Due to a lower proportion of iron oxide in the glass, the glass is much more color-neutral and is therefore better suited for the true-color presentation of pictures.

Besides real glass, "acrylic glass" (or technically: polymethyl methacrylate) is often used for framing. The best known brand is PLEXIGLAS®, which is often used as a synonym for acrylic glass in general. Even though acrylic is a plastic material, the colloquial "plastic glasses" are often made of thinner low-grade materials.

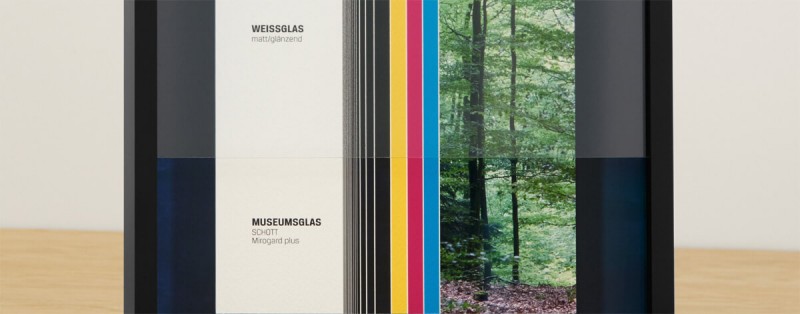

Left frame: interference-optical anti-reflective glass (left) vs. glossy window glass (right)

Surfaces:

It is the surface that gives the glass its specific properties relevant for framing. Almost all types of glass are available with different surfaces.

If no surface is specified, it is usually shiny glass. Glossy glass has a smooth, shiny surface. Glossy glass is the inexpensive standard in picture framing glass. It shows a perfect contour sharpness and is rich in contrasts - but: due to the smooth and shiny surface of the glass, the spatial surroundings are strongly reflected in the glass pane when the picture is viewed and the joy of the picture is sensitively disturbed.

If you wish to reduce reflections in the glass, you need what is colloquially called "anti-reflective" glass. What is often meant is a picture glass with a frosted, slightly structured glass surface. Strictly speaking, a distinction is made between two types of "anti-reflective glass":

Frosted glass: "Non-glare" or mistakenly also called "anti-reflective" glass. With one-sided frosted glass, the glass surface is usually roughened on one side only, by means of an etching process. The light is refracted through the uneven glass surface and so that it no longer appears glossy but matt. As a result, the image can be viewed without glare, since reflections are present but diffuse. Other effects: the luminosity of the colors or, for example, shiny areas in the image or paper are lost to a certain extent. Since the effect increases with increasing distance between glass and image surface, frosted glass must be very close to the image surface. A 3 mm passe-partout is the upper limit.

Matt vs. anti-reflective: matt white glass above, anti-reflective Artglass AR 92 below

Interference-optical anti-reflective glass or glass for museums: Genuine anti-reflective glass, correctly called "interference-optical anti-reflective glass" has a different effect. An invisible, only a few µm thick coating of metal oxides prevents reflections caused by the physical effect of destructive interference of light waves. Similar to a spectacle lens, the surface of the glass remains smooth and reflections are reduced to less than 1% by the coating. The lens is completely transparent and the image remains true to the original without any interference. "Anti-reflective" lenses are the optimal solution for unclouded enjoyment of art and meet even the highest demands of museums around the world. Unfortunately, frosted glass is often mistakenly referred to as anti-reflective glasses.

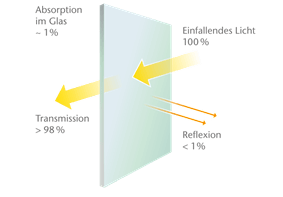

Common float glass reflects approx. 8% of incident light → Resulting in unwanted reflections

Artglass reduces reflections in the visible range to < 1% → thus allows an unaltered view of the artwork

The different glasses result from the glass type of the base material in combination with a surface. This means that there is a large number of different glasses. In addition, there are various refinements such as scratch-resistant surfaces, increased UV protection or heat treatment to make safety glass. Due to the various types of individual manufacturers and the own designations of individual dealers, there is an almost unmanageable number of glasses. For instance, we at HALBE offer the following glasses:

Standard Glass:

- Standard Glass glossy

- Standard Glass matt/glossy (one side matt, one side glossy)

- Single-pane Safety Glass glossy

- Single-pane Safety Glass matt/glossy (one side matt, one side glossy)

White Glass:

- White Glass glossy

- White Glass matt/glossy

- Artglass AR 70 (interference-optical anti-reflective white glass with 70% UV protection)

- Artglass AR 92 (interference-optical anti-reflective white glass with increased UV protection of 92%)

- Artglass AR 99 Protect (two-pane safety glass made of interference-optical anti-reflective white glass with maximum UV protection of 99%)

- SCHOTT has stopped the production of MIROGARD®. We therefore now offer the at least equivalent Artglass from Groglass.

Acrylic Glass:

- PLEXIGLAS® (acrylic glass) glossy with maximum UV protection of 99%

- PLEXIGLAS® (acrylic glass) glossy and scratch-resistant on one side with maximum UV protection of 99%

- PLEXIGLAS® (acrylic glass) matt/glossy with maximum UV protection of 99%

- Tru Vue Optium Museum Acrylic® (interference-optical anti-reflective acrylic glass, scratch-resistant on both sides and antistatic with maximum UV protection of 99%)

There is no such thing as THE perfect glass, as each one has its specific advantages and disadvantages that need to be weighed up. The art is to select the ideal glass for each application. This article is intended to provide you with the necessary background knowledge to make an informed decision.

You can get an impression of the different surfaces in this comparison video or at www.HALBE.de/en/know-how/picture-glass/. Costumers at a museum who would like to have original glass samples in their hands can request free samples from us in cooperation with SCHOTT and Tru Vue.

Here we reveal the secret of the interference-optical anti-reflective glasses - also known as glasses for museums - and look at their effect, function, manufacture and durability.

Reflection-free view thanks to anti-reflective museum glass in the Städel Museum Frankfurt/Main

Interference-optically anti-reflective glass, whether as white glass, double-pane safety glass or acrylic glass, is the top class of picture glazing and, especially in museum exhibition areas, is the best for optimal picture presentation for an unclouded enjoyment of art. We have been observing a steadily growing trend towards anti-reflective glass for years. The best-known manufacturers are Groglass with the Artglass series of mineral glasses and Tru Vue with the acrylic glass Optium Museum Acrylic®, among others.

But what does the term interference optics actually mean?

Zero Reflexion due to Counter-Rotating Light Waves

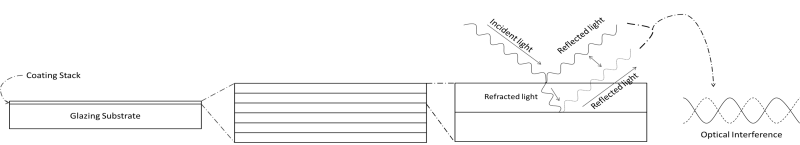

In an interference-optical antireflection coating, the base material (usually white glass or acrylic glass) is coated with a number of thin layers of metal oxide, each of which reflects a different wavelength range of light. The visible light waves are reflected in such a way that the different light waves cancel each other out, reducing the reflection by over 99%. This effect is called optical destructive interference.

Source: Tru Vue Inc.

But how does that work exactly? When light falls on the first coating layer, one part is absorbed, one part is reflected and one part passes through. When the passing light reaches the next layer, the same process happens again. The light waves reflected from each layer of material interact with each other. Depending on the length and energy of the reflected waves, this interaction causes the opposing light waves to cancel each other out. A color-neutral light transmission is guaranteed. The prerequisite for freedom from reflection is a viewing angle of 90° to the glass surface, which is especially the case when hanging frames in museums.

Layer structure of an interference-optical antireflective glass

Source: Tru Vue Inc.

To achieve this, 4-7 layers of different metal oxides are applied, depending on the product. The exact composition, layer thickness and exact number are a trade secret of the respective manufacturers. Typically, titanium dioxide and silicon dioxide (more precisely: TiOx, SiO2, Sn-ArH2, SnO2 or NbOx) are used.

Groglass and Tru Vue apply the layers by magnetron sputtering. In this process, the metal atoms are evaporated in a vacuum chamber by cathode sputtering and then deposit on the surface of the disk and bond insolubly. In total, the coating is only 0.2 micrometers thick on each side. A human hair, on the other hand, is about 500 micrometers thick. To apply the different layers, each Optium Museum Acrylic® sheet at Tru Vue passes through a coating line more than 100m long - about the length of a soccer field. The coating process takes several hours in total. The technical challenge is to avoid damaging the heat-sensitive acrylic sheets during this process.

View into the magnetron sputter

Source: Tru Vue Inc.

The main difference between SCHOTT Mirogard, which is no longer available, and Artglass from Groglass is the coating process. Whereas SCHOTT coated its glass using a dipping process and then baked it in the oven, Groglass, like Tru Vue, vaporizes its glass using the so-called sputtering process. Here, the metals are vaporized by plasma in a vacuum chamber and then deposited as an extremely thin layer on the glass, forming an indissoluble bond with the surface. According to the company, the advantages of Groglass are lower energy consumption and more stable quality due to fewer coating defects. The surfaces are mechanically and chemically tested for resistance.

The process requires absolute cleanliness of the discs and the environment. Nevertheless, minimal surface defects cannot be avoided. Therefore, each manufacturer has a quality definition of the permissible defects. We at HALBE select the discs before delivery again according to higher quality standards. However, 100% flawless panes in picture frame format cannot be produced, but this is neither necessary nor practical. After all, no viewer examines the glass pane with a magnifying glass from different angles. The quality goal is an optical defect-free pane from a distance of approx. 0.5 to 1 meter. The greatest care is also required when cutting the panes to size. We grind the edges of the Artglass panes after scoring and breaking the panes for safe handling and higher break resistance. After grinding, the discs are washed with demineralized water for residue-free cleanliness. The machines are equipped with special pads to protect the surfaces. Optium Museum Acrylic® panels are sawn and cleaned without burrs. To protect them during processing and transport, the panels are equipped with a protective film on both sides. Giving the glass the above-mentioned properties in high quality requires a highly technical process, complex production lines, high-quality base materials and high energy consumption, which also explains the extra cost.

Matt vs. anti-reflective. Matt white glass above, anti-reflective Artglass AR 92 below

Interference-optical coatings are absolutely color-neutral and, by eliminating reflections, even provide better color rendering, especially of dark colors. Thus, Artglass offers a color rendering index of Ra=100. Normal glass, in comparison, only has an index of Ra=90.

UV Protection

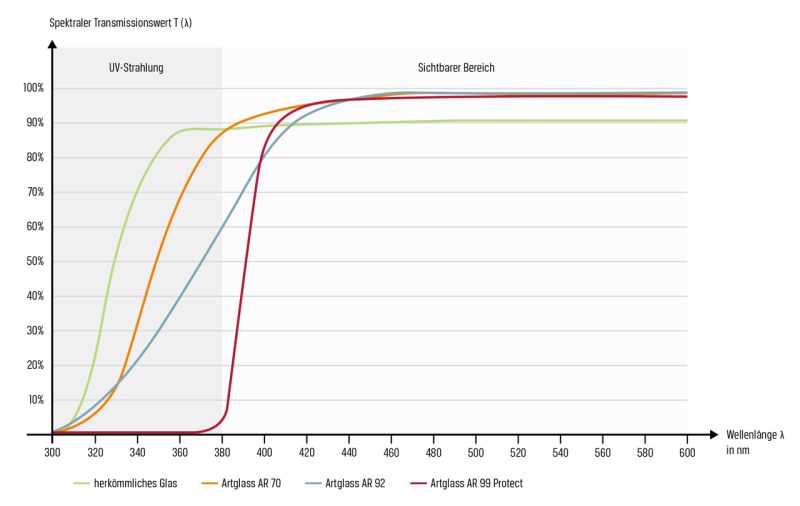

Even though many museums are free of UV radiation due to modern LED lighting, high UV protection is still a sought-after feature. Outside of museum exhibition rooms, UV protection is mandatory for the presentation of sensitive works. Glasses without special UV protection only protect against approx. 45% of the rays, so they offer hardly any UV protection. UV protection means blocking light up to 380nm wavelengths. For UV protection beyond this, the glasses are further refined.

Transmission curves of different glasses

With mineral glasses such as Artglass AR 92, a UV protection of 92% is achieved by an additional coating based on silicon oxide. Here, too, the effect of interference is used so that UV waves cancel each other out.

In double-pane safety glass such as Artglass AR 99, the laminated PVB film between the panes provides over 99% protection against UV radiation. Here, the plastic film contains the UV filter. The situation is similar with Optium Museum Acrylic®. Here the UV filter is incorporated into the acrylic glass. In this way the glass also achieves a protection of over 99%.

Blocking UV rays affects color rendering because the filter extends slightly into the visible range. Glasses with high UV protection therefore have a minimal yellow tint, but this is only noticeable in direct comparison with white glass. When developing the UV filter, Tru Vue worked with restorers and curators, for example, to find the ideal balance between maximum UV protection and color neutrality. In this way, the aesthetics and intention of a work of art are not compromised.

Surface Durability

The interference-optical coating is extremely durable, solvent-resistant and inseparably bonded to the glass surface. Interference optical coatings have proven themselves for over 55 years. Tru Vue's aging tests in a Q-Sun xenon light test chamber show no deterioration after 2000 hours of illumination with 1W/m^2 @ 420 nm at 30 ºC (which is equivalent to indoor sunlight), so it can be expected to last over 100 years.

The resistance of the coating is also tested in a standardized way.

Groglass tests the surface durability with various mechanical and chemical testing methods like abrasion resistance according to MIL-M13508C and EN 1096-2 as well as solubility ot the coating according to MIL-C-48497A. All quality and durability testing you find here.

Tru Vue tests according to American procedures. For example, the coating of Optium Museum Acrylic® shows no deterioration after 600 movements of a dry or alcohol-soaked cotton cloth with approx. 1kg pressure and 1cm diameter (MIL-C14806A, MIL-M-13508C, ASTM d5402-06). It withstands the rapid removal of an adhesive tape (MIL-C-48497A) as well as 48 hours salt spray exposure at 50°C, 95% RH (ASTM B117 & B-368-03 & B368-97). It is also resistant to salt solution, acetone, ethyl alcohol, isopropyl alcohol, and also coffee or cola. It goes without saying that the UV resistance is maintained.

In this last part we will deal with the handling of glass in practice. What role do weight and shatter resistance play? How do glass and lighting play together ideally? How do you clean without streaks and which glass do you use for what purpose?

Weight and Safety

When using glass in picture frames, not only the appearance and protection of the picture are important, but also safe and comfortable handling during framing, transport and hanging. Usually a shatterproof and light glass is preferable.

For protection against vandalism, theft but also against unintentional damage or during transport, it is essential that the panes do not break and, if they do, shards will not damage the objects or injure people. In this case, two-pane safety glass (LSG) such as Artglass AR 99 Protect or acrylic glass such as Tru Vue Optium Museum Acrylic® is used. Artglass AR 99 Protect consists of two 2mm thick white glass panes that are bonded with a special UV-absorbing film (PVB film; thickness = 0.38 mm). This film prevents loose shards in case of breakage.

No loose shards with Artglass AR 99 Protect

In Optium Museum Acrylic®, the basic material acrylic glass is inherently impact-resistant and therefore insensitive to breakage. This means that the material thickness can be less than that of mineral glass and breakage during (improper) handling is ruled out. Glass breakage during transport is also prevented.

Impact resistance of acrylic glass

Normal Artglass can be taped for transport so that in case of breakage no shards will damage the object. However, it is costly and requires suitable adhesive tape.

For more delicate frames, large works and handling, weight also plays a role. Here acrylic glass offers advantages. It is only about half as heavy as real glass with the same thickness. For example:

600x800 4,4mm Artglass AR 99 Protect – ca. 4600 g

600x800 3mm Optium Museum Acrylic® – 1730g

However, normal acrylic, such as PLEXIGLAS®, is much more sensitive to scratches due to the softer base material and becomes statically charged when the protective film is cleaned or removed, which makes cleaning more difficult and can attract filigree framed sheets. The charge must be removed with special cleaner. Therefore, it is only conditionally recommendable for museums, also because of the lack of anti-reflection coating.

Not so with Optium Museum Acrylic® from Tru Vue. It combines the advantages of low weight and break resistance with the hard surface and low static charge known only from real glass. The glass is specially treated to reduce static charge, so that any charge that occurs is dissipated within 0.01 seconds. This prevents a high level of charge from building up, which subsequently leads to the attraction of particles. This makes Optium Museum Acrylic® 2000 times less sensitive to static charge than normal acrylic glass, regardless of the manufacturer. Because it protects against static electricity, this acrylic glass is also suitable for framing sensitive works such as pastels or charcoal drawings. Cleaning is also much easier, as it does not attract dust. Especially when large series are framed, the cleaning of the glass is an important time factor. The Optium Museum Acrylic® also has a scratch-resistant surface that prevents micro-scratches through cleaning and handling. Since only the surface is "hardened", deep scratches caused by strong mechanical impact, e.g. from sharp objects, are not prevented. Here, real glass is even more resistant.

A sharp lighting angle throws residual reflections towards the floor, making the glass for museums seem to be reflection-free

Source: Tru Vue Inc.

An optical interference antireflection coating reduces reflection by more than 99%, which in reverse still means a slight residual reflection, greenish, bluish to violet depending on the product. This is normal and is part of the character of anti-reflective glasses. The coloration can vary slightly from pane to pane. How strong the residual reflection is perceived depends on the light intensity and angle of incidence. Weak, diffuse lighting with a low light spectrum and at an acute angle to the glass surface causes residual reflection to disappear. The glass is no longer perceptible, i.e. it is invisible and allows an undisturbed view of the image.

The green or bluish coloration of the residual reflection is, by the way, chosen with care, as it is the most pleasant color for the viewer. From a purely technical point of view, other colors would also be conceivable.

f.l.t.r. normal glass glossy, white glass matt on one side, anti-reflective glass directly opposite a window

Directly opposite windows, anti-reflective glass is only suitable to a limited extent, as the residual reflections are noticeable here. This is because daylight falls with the entire visible range of light almost frontally onto the pane. The visibility of the object is of course nevertheless far better than with a shiny glass, which in the same position looks more like a mirror. Compared to windows, the diffuse reflections of frosted glass appear most pleasantly.

Of course, a reflection-free optic also requires reflection-free objects. Papers and objects with frosted surfaces are ideal. The surface of a high-gloss photo paper will continue to reflect even behind interference-optically anti-reflective glass. Only frosted glass can help here. If you want to present works with matt and glossy surfaces as if they were without glass, you must resort to anti-reflective glass.

Cleaning

Anti-reflective glasses require a little more care when cleaning, as cleaning residues are more likely to be visible on the coated glass surface than on normal glass. It is best to avoid soiling as far as possible. It is therefore advisable to wear thin cotton gloves when handling the panes - regardless of the type of glass. Glass panes can be gripped well by touching them only at the edges. The outstretched fingers press against the edge only at the sides.

Light soiling such as fingerprints or dust can be removed most easily with a dry soft cloth. Normal soiling can be removed with a clean cloth with - ideally distilled - water. Artglass panes can be cleaned easily with Cif Professional glass cleaner. While the water in combination with a microfiber cloth is also very suitable for Optium Museum Acrylic®, the Cif cleaner leaves streaks. The professional never sprays the cleaner directly onto the windshield, but always onto the cloth. It is recommended that you always wipe the windows dry with a second cloth. The cloths used should be lint-free.

Strong alkaline detergents, acids or mechanical cleaning agents (scouring milk, steel wool, blades) must not be used. Glass cleaners containing ammonia should generally not be used for framing to prevent damage to the framed pictures. Coatings are not attacked by the ammonia. Optium Museum Acryilc® must not be cleaned or treated with typical acrylic glass cleaners or polishes for uncoated acrylic glass, this would damage the coating.

Application

In the end, one question remains: which glass is the right one for me? There is no perfect glass. Every type of glass has its advantages and disadvantages. The art is to choose the right glass for an application that also fits the budget. To do this, you have to be sure about your requirements for image reproduction, UV protection, break resistance.

If there are no special requirements for brilliance and UV protection, e.g. when framing your own advertising posters in the entrance area, for information texts or if the budget is small, frosted glass is a good and inexpensive choice, for best color reproduction the white glass can be used. If UV protection or break resistance are still required, or if large-format works (over 1200x1400mm) are framed, PLEXIGLAS® is a good alternative.

If you want to offer your visitors an undisturbed view of the pictures, interference-optical anti-reflective glasses are the clear recommendation.

If framed works of art are only brought into your own showrooms, the comparatively inexpensive Artglass AR 70 is recommended. As soon as UV protection is required, Artglass AR 92, Artglass AR 99 Protect or Tru Vue Optium Museum Acrylic® comes into play. The latter two offer over 99% UV protection and high break resistance.

If low weight is also required or works of art up to 1.8x3 meters are glazed, only Optium Museum Acrylic® in 3mm, 4.5mm or 6mm thickness is suitable. Acrylic glass tends to become slightly bulbous from certain sizes onwards, as the material is minimally flexible. Tru Vue therefore recommends using thicker sheets for large sizes to ensure good flatness. The recommendation is:

3mm to 1016x1016mm

4,5mm from 1017x1017mm to 1524x1524mm

6mm from 1525x1525mm

Experience has shown that the cheaper 3mm discs are also suitable for larger frames. For oversized glazing in the USA, 6mm Optium Museum Acrylic panes have already been glued together over 6 meters in length. When using acrylic panes, it must be noted that the material grows and shrinks due to changes in temperature. The coefficient of thermal expansion is approximately 0.07. There must therefore be sufficient clearance and coverage to compensate for the changes.

With us you can get not only complete frames, but also individual panes cut exactly to size. Often the old glass can be exchanged for new panes in existing frames and thus the frame stock can be modernized sustainably.

Reibrad Test

DIN ISO 3537 2018

Testbedingungen

Funktionsprinzip

Was wird getestet?

Abriebfestigkeit der Beschichtung im täglichen Gebrauch, z. B. bei Reinigung des Glases

SCHOTT MIROGARD®

O.K.

Klebeband Test

Testbedingungen

Ein Klebeband wird innerhalb einer Sekunde vom beschichteten Glas gerissen

Was wird getestet?

Haftvermögen der Beschichtung z.B. wenn Aufkleber aufgeklebt werden

SCHOTT MIROGARD®

O.K.

Alkohol Abriebtest

Testbedingungen

2 Gewichte a 3,5 kg mit Filzboden werden in Alkohol getaucht und 100 x über das Glas gerieben

Was wird getestet?

Beständigkeit der Beschichtung gegen alkoholhaltige Flüssigkeiten

SCHOTT MIROGARD®

O.K.

Griffel Test

Testbedingungen

2 Griffel mit Eisenspitzen und 1 Griffel mit einer Messingspitze werden für drei Runden mit leichtem Druck über die Glasoberfläche geführt

Was wird getestet?

Kratzfestigkeit der Beschichtung bei Berührung mit harten Gegenständen

SCHOTT MIROGARD®

O.K.

Transmission curves of different glasses