Behind the scenes of Tru Vue®

High-quality, interference-optical anti-reflective glass, or glass for museums, has a firm place in the world of picture frames . It protects sensitive works on paper from dust, dirt, contact and harmful UV radiation. At the same time, it should allow the viewer as unclouded a view of the picture as possible. This means that it must reproduce colours undistorted and reduce reflections as best as possible.

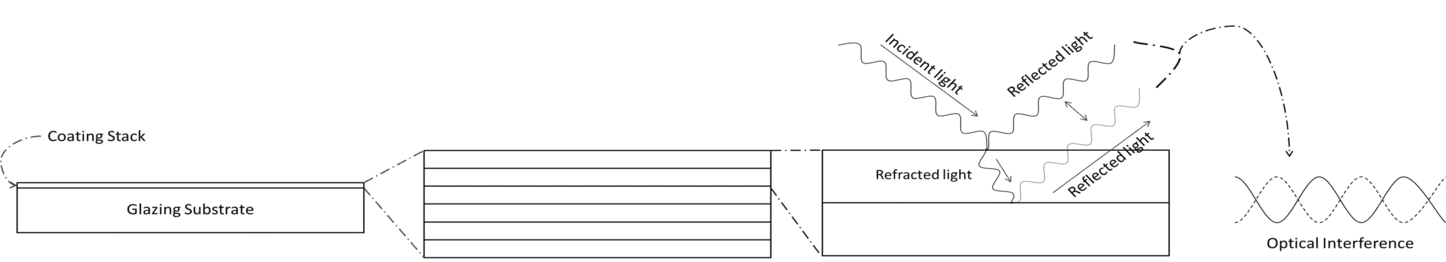

Optical interference anti-reflection coating - What is it?

In short, optical interference coating means that the glass is coated with many thin layers of metal oxide, each of which reflects a different wavelength of light. The visible light waves are then reflected back in such a way that they cancel each other out. This reduces the otherwise distracting reflection in the glass by over 99%. The various layers are only 0.2 micrometers thick in total - a fraction of a human hair (about 500 micrometers).

Behind the Scenes: Tru Vue®

One of the largest manufacturers of museum glass, Tru Vue®, now gives an exclusive insight into the complex production of its high-quality museum glass and Optium Museum Acrylic®. The Tru Vue® plant in Faribault, Minnesota (USA) is state of the art and produces interference optical anti-reflective glass around the clock. In the more than 200m long machine, Tru Vue® (acrylic) glass is coated in a vacuum chamber using so-called magnetron sputtering. The metal atoms are atomized and evenly applied to the pane in several layers without damaging it.

You can see for yourself how this works and what it looks like in the manufacturer's high-tech factory in a behind-the-scenes video:

You can find additional information about the various glasses for musuems in our knowledge section. We will also be happy to advise you personally on your frame and glass selection.