from left to right: Sabine, Susanne

Final Assembly

When individual parts form a larger whole

Sometimes we also frame larger series or certificates for our customers. This is particularly exciting, because often we do not get to see the works that come into the frame. To see the different works in this way or to be among the first to know about the award winners makes us proud. For very large frames, our largest dimension is 2x3 meters, we get active support. We regularly take turns with Jutta, Birgit, Eva and Astrid.

Sabine

I have been here since 1987. I came here by luck. On the way to my previous job, my car broke down. When I was late for work, of course, I was reprimanded by my boss. So I took off my smock again and unceremoniously quit. On the way back, not knowing what was being produced at HALBE, I drove by and asked for a job. Mr. Halbe only replied if anyone had called me before, because moments before they were talking about an open position. And so I stayed. Over the years I have worked in every department and there have been many special moments, but the company excursions have always been unique. I especially care about the quality and cleanliness of my work. The photo frame is definitely one of my favorites.

We are Sabine, Susanne, Jasmin, Murat, Sascha and Sufian. When the individual parts of your frame are ready, we assemble everything to the complete frame, pack and pick the orders. No matter if Classic, Distance, B1 or Conservo. Only the special Protect magnetic frame are assembled by Tim and Lilli. Each element is provided to us by the other stations in the correct order. We take the parts and assemble them to a complete frame and check everything again. We put your ordered mounts directly into the frame, so that they are well protected during transport. Afterwards, we pack everything and pass on the completed orders to the shipping department, where Dominik, Andreas and Leo take care of them.

Susanne

I have been working for HALBE since January 1981. I introduced myself on 20.1 and was able to start on 21.1 - so uncomplicated. I was able to gain experience for my current department at the basic elements and glass stations. It also taught me the value of cleanliness, order and working to perfection. One of the funniest moments was undoubtedly the day Birgit was hired in 1989. One of my favourite frames is a 594x840mm Classic Alu 8 in brushed stainless steel.

Jasmine

I started at HALBE in in February 2022 after applying for a job advertisement. I couldn't help it because I live just around the corner and can easily walk to work in the morning. My previous stations in the company were final assembly, service and accessories. In my work, I pay particular attention to cleanliness and the accuracy of fit of a frame. Above all, I am always impressed by how well my colleagues work together. My favorite frame is made of walnut in wood 22.

Murat

I've been part of the HALBE team since mid-2021 - it was an absolute stroke of luck that I joined HALBE. My areas of responsibility so far have been the basic elements department, final assembly, shipping and the sheet metal department. At work, we pay particular attention to maintaining customer satisfaction and the quality of our products. This is what HALBE Rahmen has stood for with its good name for 75 years. One of my favorite frames by far is a wooden frame in walnut. Working at HALBE is really great, especially because of the family atmosphere. A funny moment by far was looking through our employee photos, it was really funny and a lot of fun.

Sascha

I have been working at HALBE since July 2021 and this is my second time. As I already knew HALBE very well, it was clear to me that I would apply when I saw the job advertisement. So far, I've worked in dispatch, the wood department, upsetting and final assembly. I am now a team leader here. In my day-to-day work, I attach great importance to good teamwork, honesty, product quality and punctuality. An old illuminated frame has been with me for many years, but I also own many other frames in stainless steel or natural ash wood and I am proud of them. One of the special moments at HALBE is having a barbecue with my colleagues.

Sufian

I joined HALBE in September 2020 and from day one I felt like I had become part of a big family. So far I've worked in the aluminum saw, the sheet metal department and in shipping. It's been a great experience to have worked in so many departments. I care a lot about the good quality of our products. I also really appreciate the working environment, the flexibility and the good relationship with my colleagues and boss. I really enjoy our annual outings, the Friday barbecue and every day when you can have fun with your colleagues despite the hard work. My absolute favorite frames are an Alu 12 and a DISTANCE frame in wood 22.

How our customers frame

Nils Dunkel at the Kunstakademie...

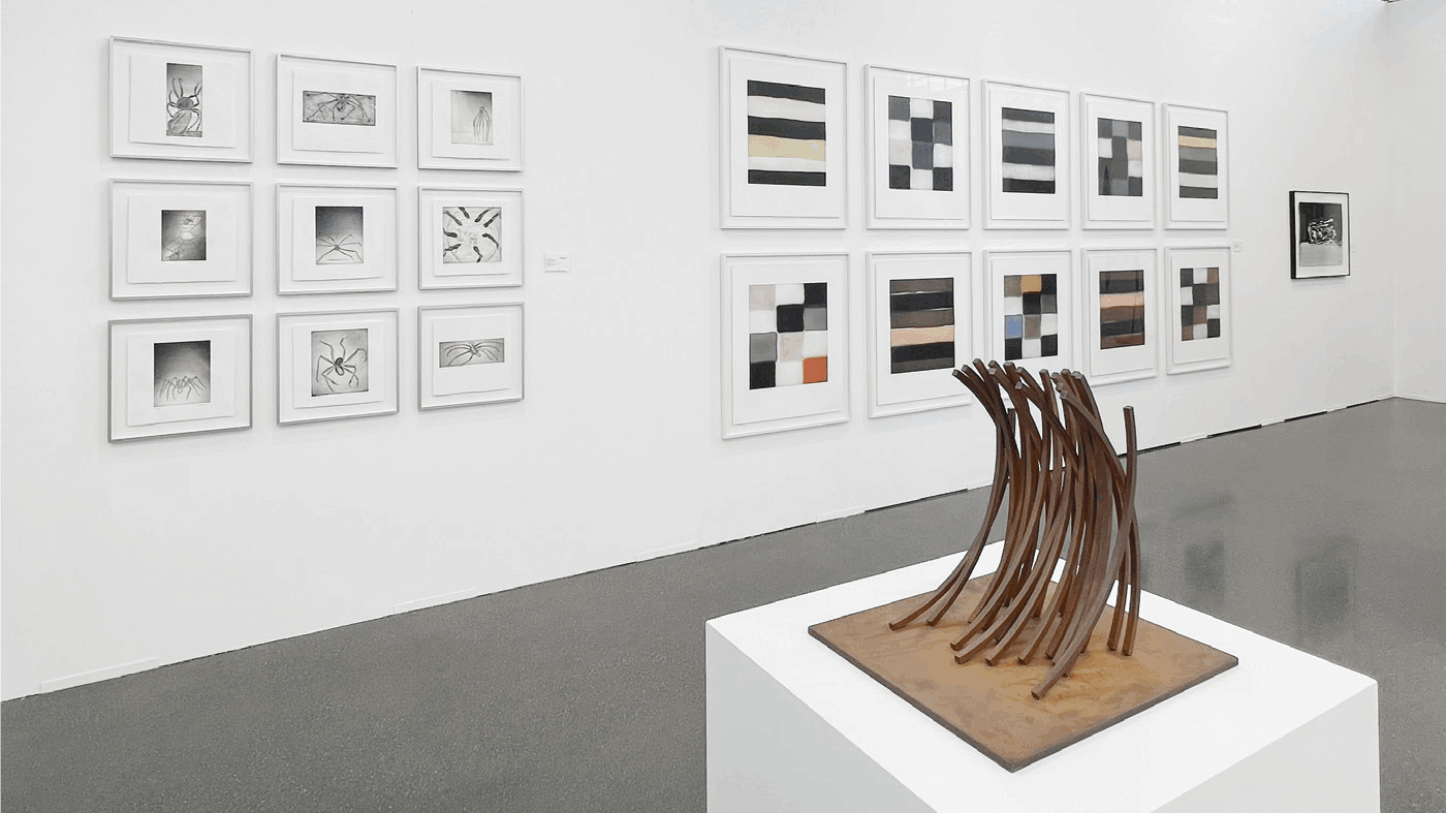

Galerie Boisserée at Art Düsseldorf 2023

Nikola Dimitrov at the Fetzer Gallery

Inspired by Edward Steichen – Erwin...

How our customers frame

Nils Dunkel at the Kunstakademie...

Galerie Boisserée at Art Düsseldorf 2023