from left to right: Dominik, Andreas, Leo

Shipping / Warehouse

So that your frames arrive in one piece.

The packaging must ensure the safe transport of the frames. That is why we have developed particularly resilient packaging. Statically super well thought out. We ship all our frames in this packaging. To improve our packaging, we regularly carry out drop tests. In our endurance tests, we drop a package 10 times - even on the edges. That lasts. Because our department is also very concerned with sustainability, the packaging and cushioning material is recycled corrugated cardboard and can be easily recycled again. Our parcel shipping with GLS and DPD is climate neutral. Minimal packaging volume, custom shipping packaging reduces transportation volume and the use of packaging and cushioning material. Our cardboard boxes used are made of recycled paper and we produce the filling material ourselves.

Many years ago, we were impressed by a crazy experiment on the resilience of cardboard. Students from Karlsruhe built a complete car bridge out of corrugated cardboard and let a car drive over it. It worked really well and convinced us.

Alexander

I've been here since March 2020. At that time, they were looking for a new colleague in the dispatch department and I've been here ever since. During that time, I've already worked in final assembly and in the sheet metal department in addition to my current department. The fact that I now get my hands on the frames at the end in the dispatch department means that completeness and thoroughness are very important to me. One of my favorites is every frame that reaches the customer in one piece. I think that every day is a special day because it's always fun to come to work.

We are Alexander, Manuel, Florian and Leo, we are responsible for shipping at HALBE frames. Into the box and ready. Sounds as simple as the magnetic system of our frames. But we have also experimented with packaging for years and have come up with a solution that is pretty good for us. This also includes a machine for dimensionally accurate shipping cartons. This enables us to make an exactly fitting box for every order. Nothing wobbles or jolts during shipping.

Manuel

I've been with the company since August 2023, thanks to a recommendation from Dominik, who used to work at HALBE. I started in shipping and now take care of the safe packaging and fast shipping of all frames. I have also already built insert frames. I attach great importance to regular work with as little ambiguity as possible and good communication within the team. One of my highlights so far has definitely been the company outing in Bad Marienberg, because you get to know your colleagues in a completely different way on occasions like this.

Leo

I started working at HALBE in 2000 because my wife also worked here and was always satisfied. For many years I worked in the shipping department. At the moment I am responsible for the receiving department and I am sawing plexiglass where absolute accuracy is important. Our products are special to me, which is why I don't have one frame, but several.

Florian

I started working for HALBE in October 2023. I first heard about HALBE because we bought the house from Hubert Halbe, David's grandfather and company founder. In my short time there, I mainly worked in dispatch and also in final assembly. In every department, I realized again and again how important cleanliness, orderly work, collegial and respectful cooperation are. Unfortunately, I don't have a favorite frame yet, but I'm sure there will be one soon.

How our customers frame

Nils Dunkel at the Kunstakademie...

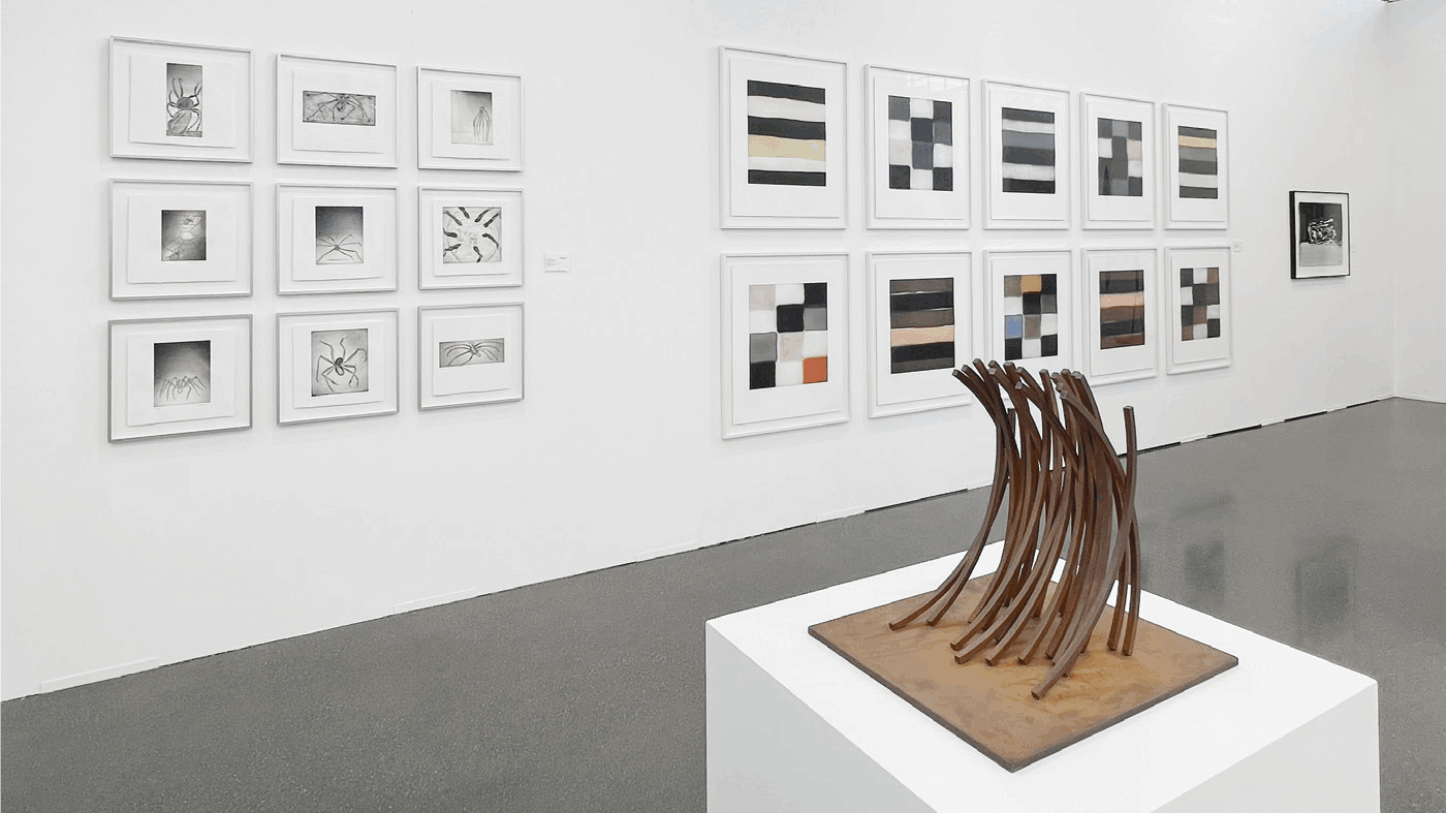

Galerie Boisserée at Art Düsseldorf 2023

Nikola Dimitrov at the Fetzer Gallery

Inspired by Edward Steichen – Erwin...

How our customers frame

Nils Dunkel at the Kunstakademie...

Galerie Boisserée at Art Düsseldorf 2023